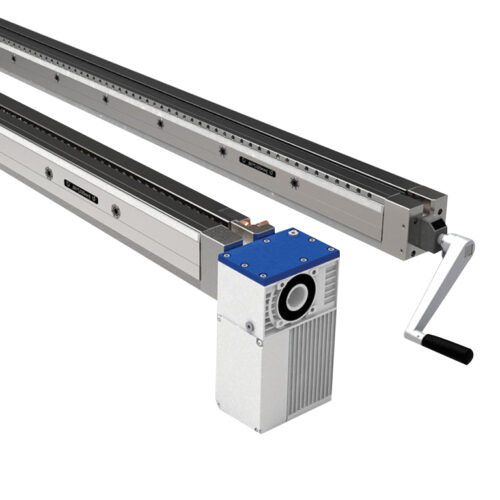

- Set screws every inch along the beam for manual tightening

- Use the hand crank with digital display, or

- Use the machine’s CNC control to adjust the crown via an electric motor.

- Overall crowning capability adjusts the beam up to 2.5mm to 3.5mm (depending on length)

- Micro crowning, for fine-tuning adjustment, is available at points every 200mm (7.78”) on the beam. Micro-crown adjusts up to .76mm (.030”)

-

Request a quote for price.

-

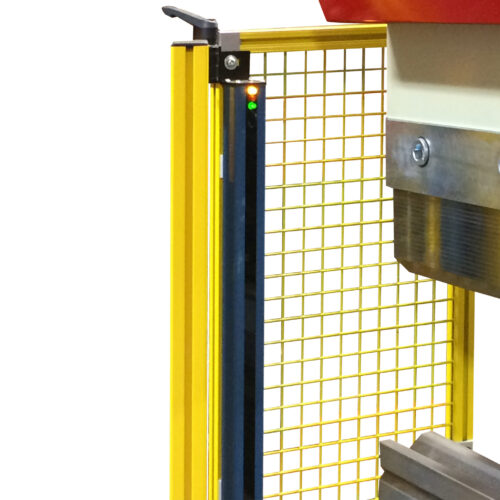

Only works with Conventional Press Brakes

- User friendly

- Continual system status checks

- Easily viewed message display

- Meets OSHA, UL, ANSI, CSA, RIA, and CE standards

- Light curtains swings out of the way when not in use.

-

• Hydraulic power source • Longer life due to a hardened body • Quick clamping for American and WT style tooling • Automatic fluid level monitoring for greater reliability • Simple push-button loading • Wireless pendant control

-

Automatic Axes: X, R Manual Axes: Z1, Z2, X5, X6 X Stroke: 600mm (Optional 800 and 1000mm) R Stroke: 150mm (Optional 200 and 250mm) MADE IN ITALY

-

Automatic Axes: X, R Manual Axes: Z1, Z2, X5, X6 X Stroke: 600mm (Optional 800 and 1000mm) R Stroke: 150mm (Optional 200 and 250mm) MADE IN ITALY

-

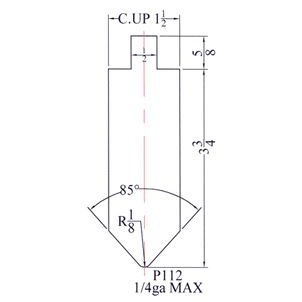

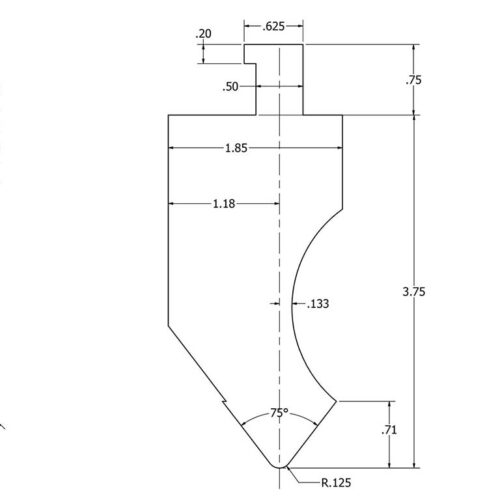

75º Gooseneck punch Configurable in .25" increments from 1" to 53.5" 1", 1.25", 1.5", 1.75", 2", 3", 4", 5", 12", and 18" Lengths Included

-

75º Gooseneck punch Configurable in .25" increments from 1" to 77.5" 1", 1.25", 1.5", 1.75", 2", 3", 4", 5", 12", 18", and 24" Lengths Included *Pictures show 53.5" set

-

75º Gooseneck punch Configurable in .25" increments from 1" to 101.5" 1", 1.25", 1.5", 1.75", 2", 3", 4", 5", 12", 18", and 24" Lengths Included *Pictures show 53.5" set

-

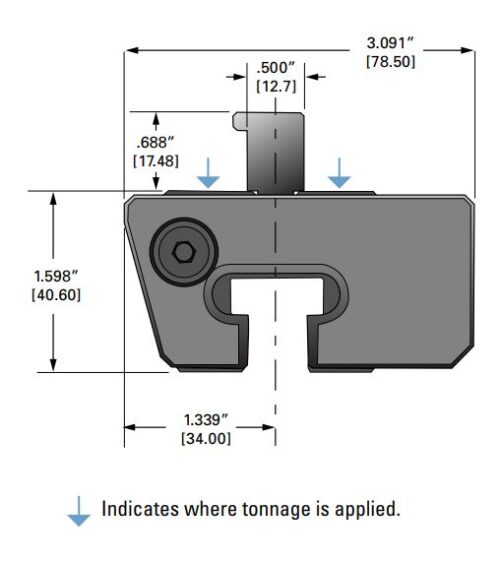

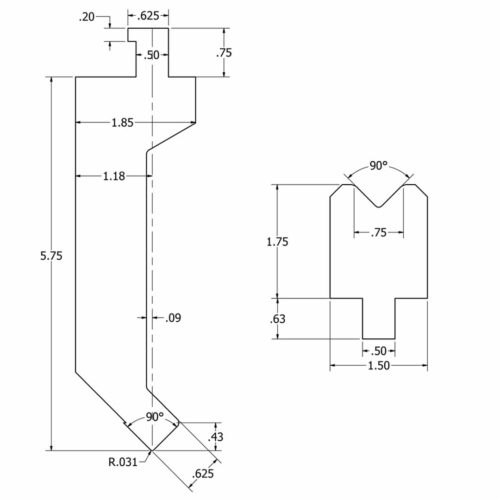

- 90 degree punch and die

- Configurable from 1" up to 53.5" in 0.25" increments

- American style safety tang

- Extra height for bigger box bends

- Meant for use with our Press Brakes