Description

– Request Quote For Price

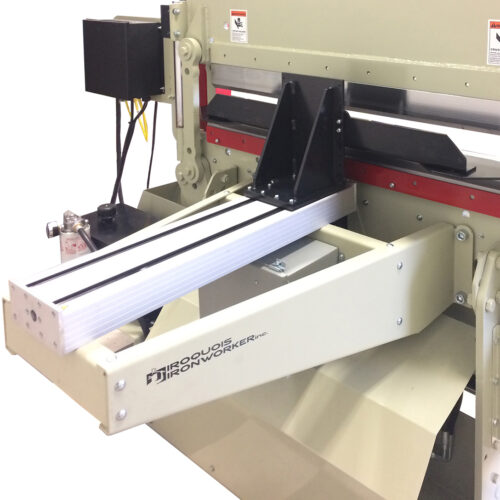

Bending a longer part on a press brake can lead to a bowed appearance in the part, or “the canoe effect” due to machine deflection. The Crowning system is the precise and consistent option for controlling deflection on your press brake. Now bending longer parts can be made precisely, efficient and consistently parallel with every run.

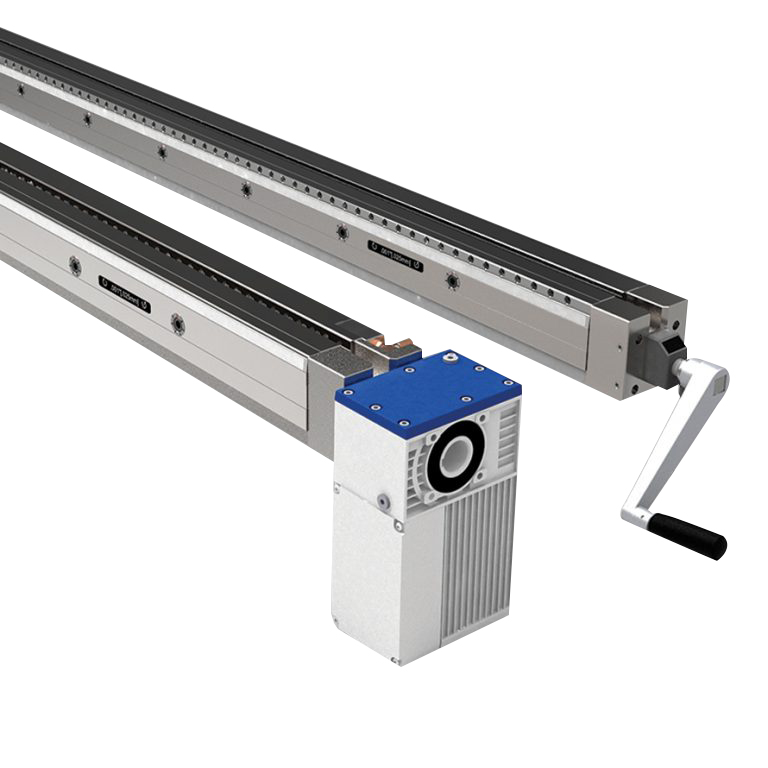

The Crowning system offers precise crowning and micro tuning. You have your choice of control for crowning power and for securing the die.

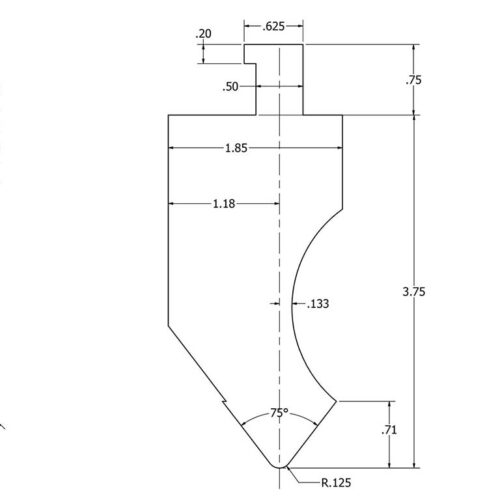

Die holding:

- Set screws every inch along the beam for manual tightening

- Use the hand crank with digital display, or

- Use the machine’s CNC control to adjust the crown via an electric motor.

- Overall crowning capability adjusts the beam up to 2.5mm to 3.5mm (depending on length)

- Micro crowning, for fine-tuning adjustment, is available at points every 200mm (7.78”) on the beam. Micro-crown adjusts up to .76mm (.030”).